Smart Skin Enables Robots to Sneak Inside Arteries or Aircraft Engines

SadaNews - In the laboratories of the University of California, San Diego, a team of engineers has developed a soft robotic skin that allows small robots, moving through growth or internal flipping, to navigate complex and fragile environments with precision and safety. This technology could open new horizons in exploring microscopic bodies from inside arteries to the corridors of aircraft engines.

The robots, with an extremely small diameter ranging from 3 to 7 millimeters and a length of about 25 centimeters, are equipped with flexible robotic skin that features tiny motors made from liquid crystal elastomer, carefully distributed at strategic points on the skin. When researchers control the temperature of these motors and balance the pressure inside the robot's body, the robot can orient itself, turn corners, balance itself, and carry a camera to inspect its surroundings.

Smart Skin in Motion

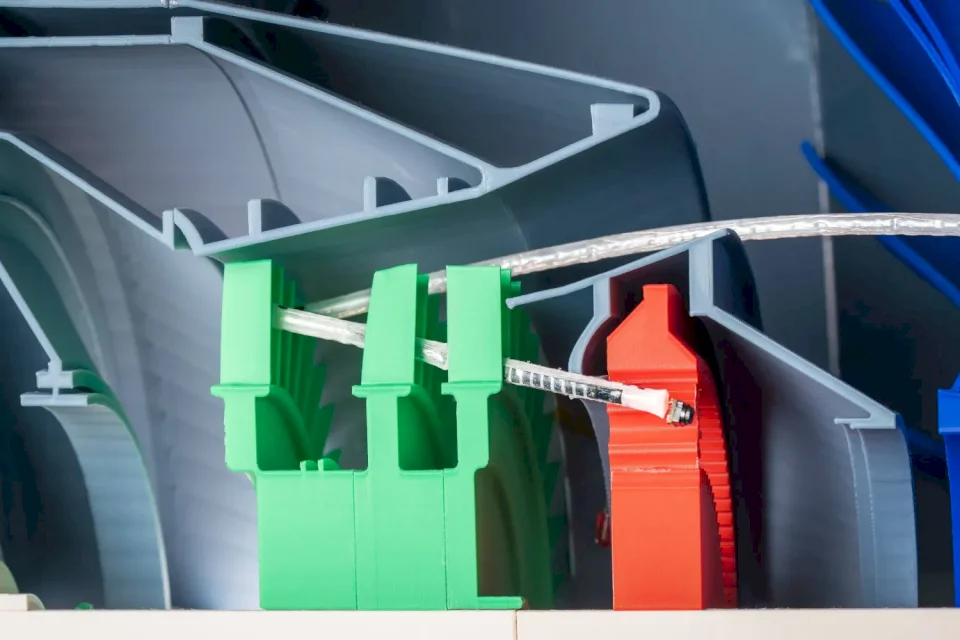

One of the key tests involved passing a robot through a model that simulates human arteries, including the complex-shaped aorta, and through very narrow gaps that were sometimes tighter than the robot's own radius. Simultaneously, this flexible skin was tested inside a model of an aircraft engine, where the robot was able to twist and inspect the complex engine architecture.

The advantage of this system lies in its high precision control. Instead of relying on pneumatic motors, wires, or strings like larger robots, the researchers integrated warmth, pressure, and heat into the robot's skin itself as an internal steering motor; thus, this skin is not merely a "cover" but an active part of the movement system.

Performance tests showed that the robot can execute sharp angles exceeding one hundred degrees throughout its structure, pass through narrow gaps, and even cling to delicate surfaces. It is also equipped with an internal camera that allows it to capture images of the internal areas of the engine model.

The greatest challenge was designing the mechanical skin to meet the delicate environment requirements by being thin yet strong, so it does not hinder movement or rotation of the robot and can withstand repeated stretching and pressure without damage. Small flexible heaters were also integrated beneath the motors to raise the temperature in a controlled manner to activate movement. Experts are working on making the technology capable of handling fluctuations in internal pressure without performance collapse.

Future Development Perspectives

Researchers aim to make the robots operate autonomously or be remotely controlled, shrinking them further so that they can enter the tiniest spaces in living organisms or industrial devices. These everting robots, where the inner skin gradually turns outward, resemble a vine that extends and permeates the void, capable of expanding while in motion.

The team believes that this technology will not be limited to medical or industrial applications only; it can also be adapted to serve as soft arms in haptic devices, or soft tweezers for picking up fragile objects, or soft-movable robots in challenging environments.

What we see today is a step toward a future where tiny machines begin to move confidently among living tissues or intricate components in machines without damaging them. This smart skin is not just an additional component but the heart of precision movement in small robots. If efforts succeed in making this skin more efficient and autonomous, we might reach an era where robots, as "skin" smaller than a hair, can detect flaws inside equipment or living bodies without leaving a trace.

Report: Internet penetration in Jordan exceeds the global average by 28%

Study: What is the effect of lack of sleep on the brain?

Between Walnuts and Peanuts: Which is Better for Heart Health?

Thyme Enters the Era of "Modern Medicine"

Data Theft of Millions of Instagram Users

Google Launches New Feature to Organize Email Subscriptions in Gmail

Biometric Voice Data... Does It Threaten Privacy in the Age of Algorithms?